CNC Turning

1-100,000+ Parts

Global Delivery

CNC Turning

Xinrong Precision is an experienced supplier of high precision CNC turning. We have always provided excellent services in CNC turning. With rich experience gained from past years, our team is able to customize parts for clients at a reasonable price. We can manufacture gaskets , gasket bolts, shafts, sleeves, chuck stainless, steel fittings, and pipe fittings. Multiple materials can be used in our manufacture, including copper, brass, stainless steel, carbon steel, aluminium and titanium.

What is CNC Turning?

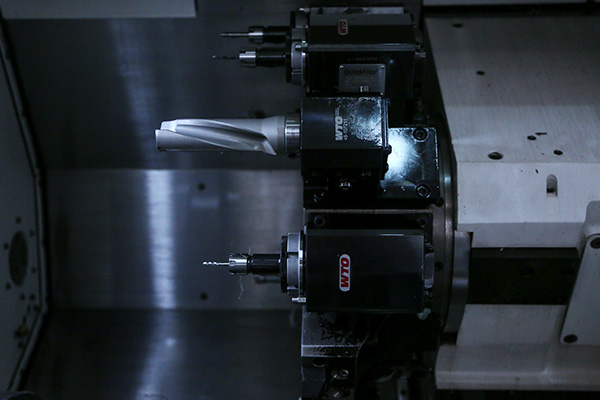

The numerical control turning is a special kind of precision machining process, which puts the cylindrical workpiece into the chuck, which spins in a specific direction. In the process, we use cutting tools to remove the superfluous parts to gain the expected parts, creating a smooth surface in pure cleanliness. This technique can be used interiorly or exteriorly, producing tubular components in distinctive geometric shapes. In numerical control turning processing, subtraction manufacturing methods are usually carried out on CNC lathes or turning centers. As the workpiece rotates, various cutters are applied to the workpiece to create circular shapes and features, such as ring groove radius inner holes and threads.

Why choose CNC turning?

CNC turning would be perfect when dealing with cylindrical- or ring-shaped parts. Firstly, this technique is highly efficienct; secondly, the finished products are of high cleanliness. The cost can be saved, but the efficiency can be improved with auxiliary equipment like automatic feeding materials.

What materials can be used in CNC turning?

Most metals ,alloys, and plastics can be used in CNC turning. Please avoid using hard materials such as hardened steal; if you have to use these materials, we could offer you special tools, but the processing time will be multiplied. Besides, soft plastics cannot be processed, because they cannot be fixed on the workbench, and their final shapes cannot be changed by milling tools.

Advantages of Xinrong Precision for CNC turning:

Our company has rich experience in CNC turning, with a sophisticated technique team, so we are able to provide high-quality parts of CNC turning for you with high reliability. Our equipment is in the brands of long acknowledged Mazak and Okuma with high precision and smart operation systems, making our manufacturing process more simple, but lowering the manufacturing cost. Our technicians are experts in the field of CNC turning. They are experienced and highly skilled, and you could get customized services easily from them.

CNC Turning

Contact us for a free quote

Our engineering team promises to offer you a quote within 24 hours after receiving your design files, and the waiting time can be cut if the file involves less degree of complexity. Our sales will keep in touch with you to ensure the quote to be handed to you.

FAQ:

1. What is the precision of CNC turning in Xinrong Precision?

Our equipment that is introduced from Japan can ensure a high precision of 0.005mm.

2. What is the maximum size and weight of your product?

Our maximum size or products is 1000mm*800mm*800mm, and the maximum weight is 2000Kg.

3. Can you process some highly hard materials?

Normally, after close examination, some milling tools like titanium alloys and other superalloys can be customized.

4. How many parts can your 5-axis machines make per month?

The production scale varies with the degree of complexity, and 500 to 100,000 parts can be manufactured each month.